|

ROV innovations have become synonymous with underwater asset inspections, specifically with assets in zero visibility water. Our ability to image complex structures such as bridges, as well as mapping river beds and obtaining hi resolution profiles has allowed us to provide our clients with images of their structures that they have never seen before. Sonar CapabilitiesOur high resolution sonar is ideal for projects such as :

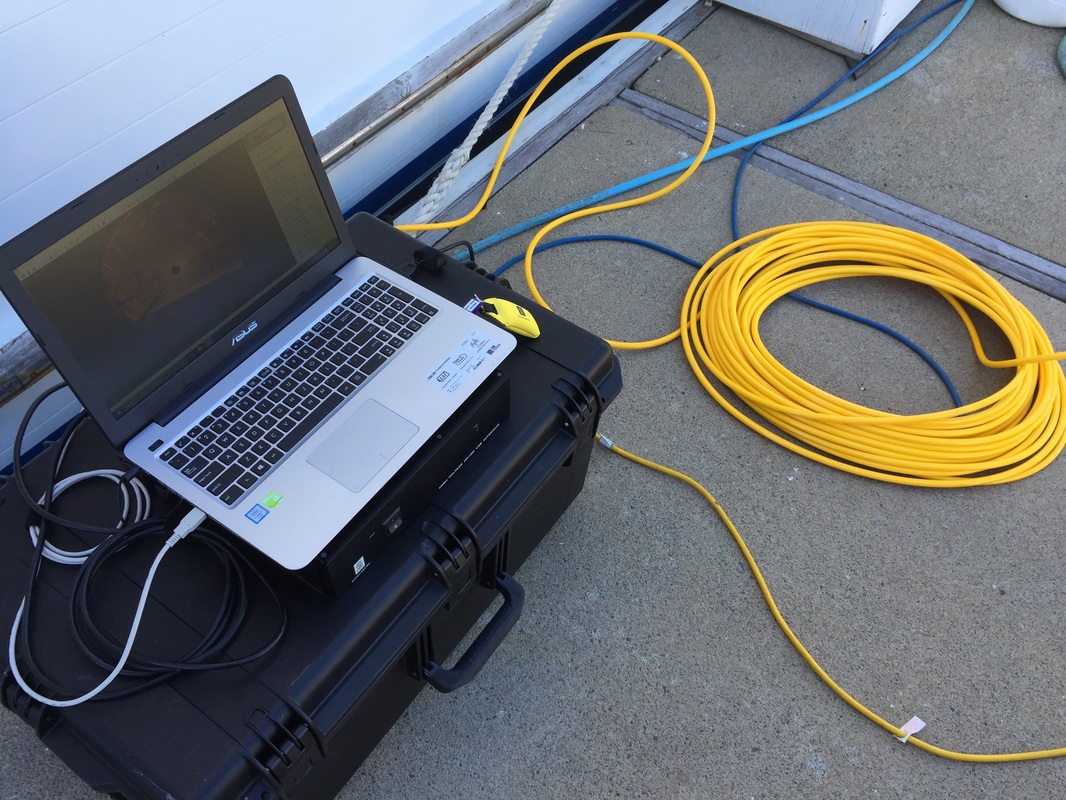

Operational PlatformOur custom designed vessel - White Shark 1 - provides us with an ideal working platform for all of our underwater inspection and survey requirements. It has a large open back deck, full-length canopy for sun and rain protection, doors on the starboard side allowing us to operate close to the water's surface, echo sounder, side scan sonar, 2000w inverter for the safe operation of all 240v equipment, hi flow water pump, twin 150 horsepower 4 stroke honda outboards, GPS, as well as a stern underwater platform that can be lowered to assist in retrieving divers or equipment from the water. Hi-Def ROVsBy combining our Sonar Imagery with that of our High Definition ROVs we can offer the highest level of confidence to our clients. We can use the high resolution imagery from the sonar to map large areas, zoom into any sonar returns that show any suspicious activity, record its precise GPS location, and then send our HD ROV directly to the anomaly and get eyes on the target to have a definitive answer for our clients. This allows us to confidently survey 100% of the area in question and also offer our clients a 100% guarantee that nothing was missed.

0 Comments

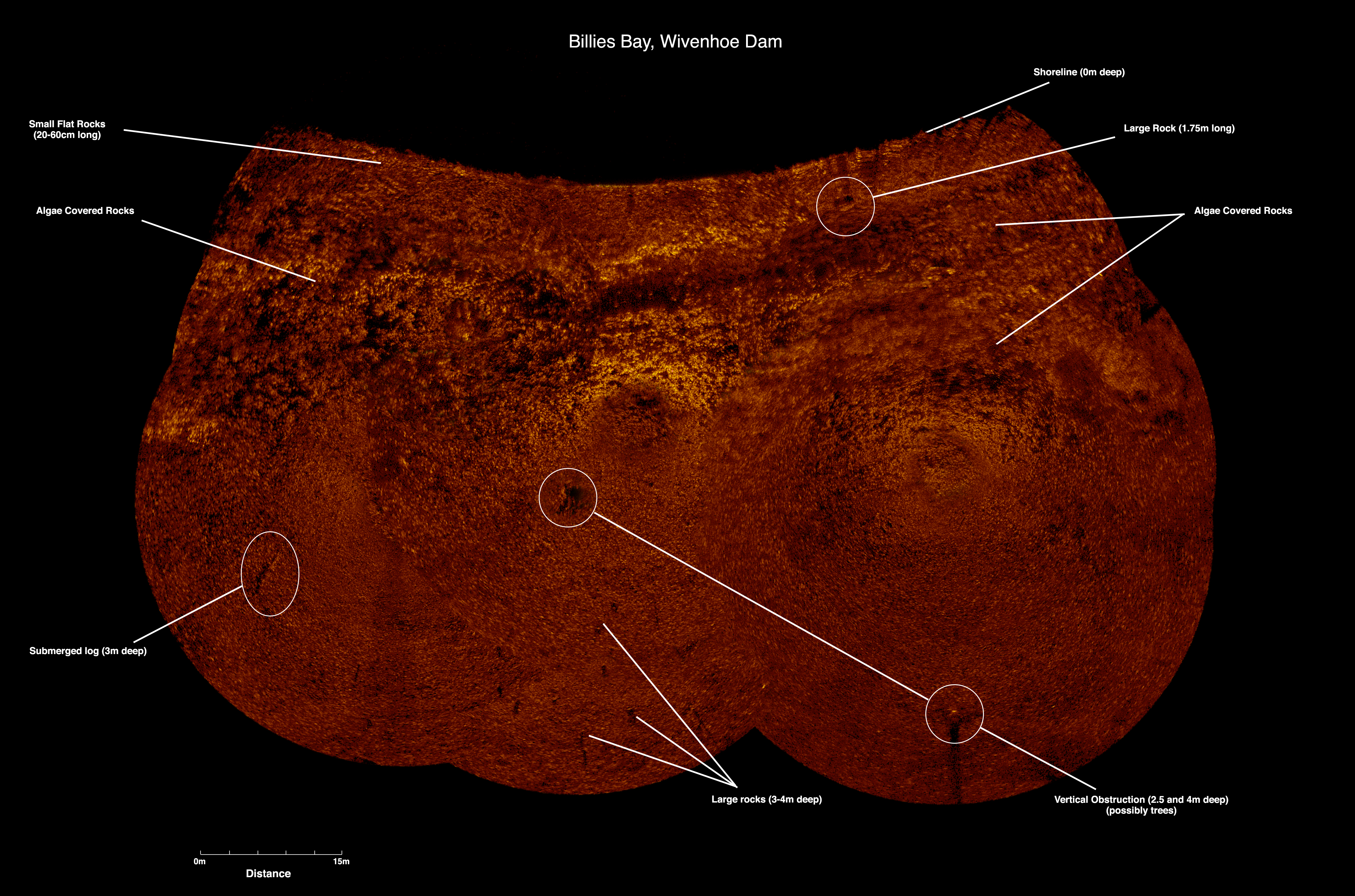

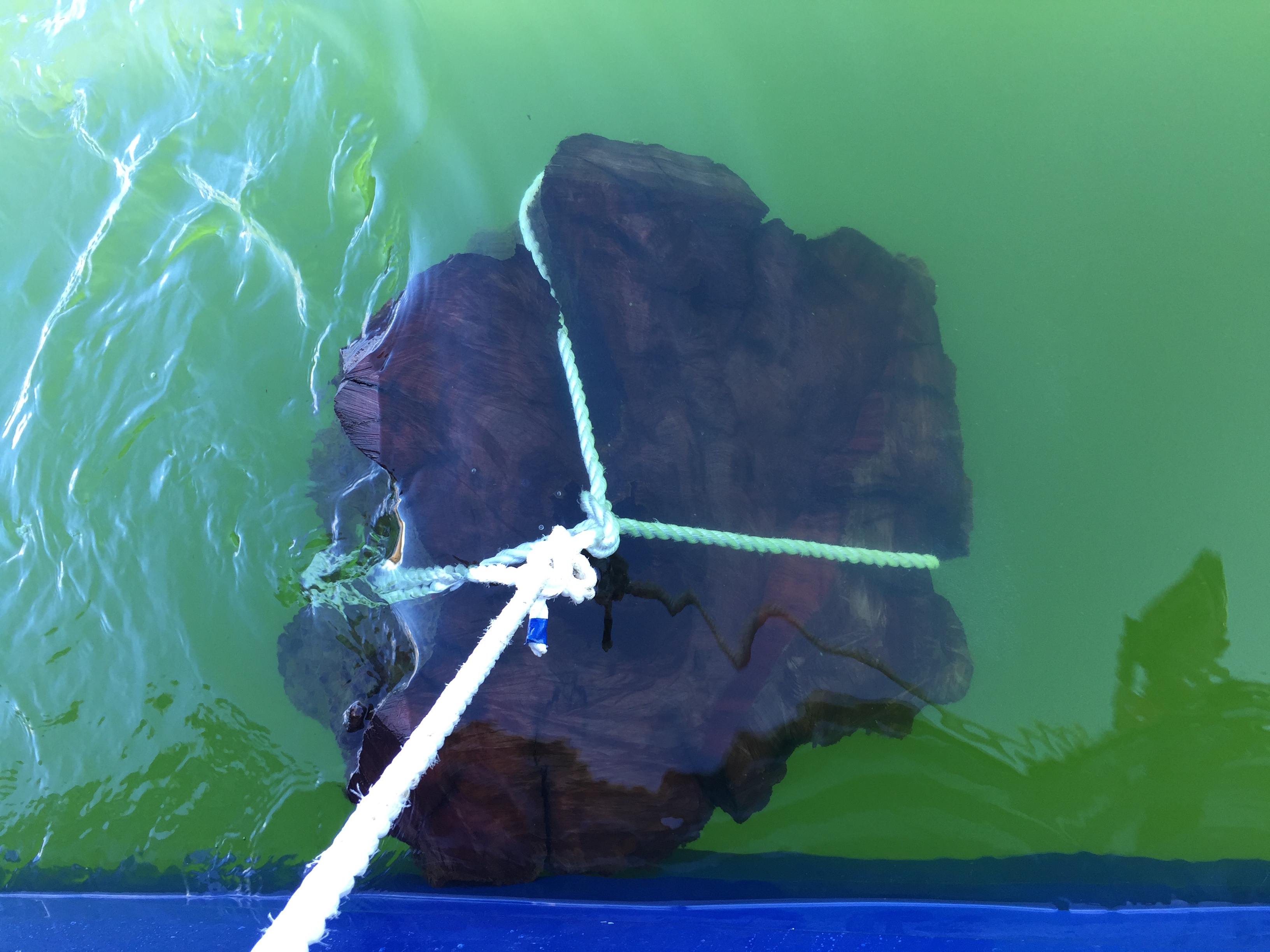

ROV Innovations has been called upon to intensively map local swimming areas for potential underwater hazards coming up to Summer in South East Queensland. Our team used our high resolution scanning sonar from our custom designed commercial vessel to map the first area in Wivenhoe Dam. We were able to quickly and efficiently identify 3 immediate hazards in the yet to be opened swimming area with the sonar, and with swift action by our client, arranged our commercial dive team to enter and remove them. In this instance, the hazards proved to be red Cedar tree stumps standing a meter tall and approximately a meter in diameter, and a 5m long log on the dam bed. Using an underwater hydraulic chainsaw, we were able to remove the potential hazards to ensure that swimmers in the area would not injure themselves. Due to the low visibility around the bed of the dam, the sonar proved to be the only reliable method to identify any potential hazards to swimmers. Using either Divers or ROVs in this instance would not be viable as they could easily have missed these hazards by a meter and not seen them. Only the high resolution scanning sonar allowed us to have 100% confidence that we had covered the entire area of concern.

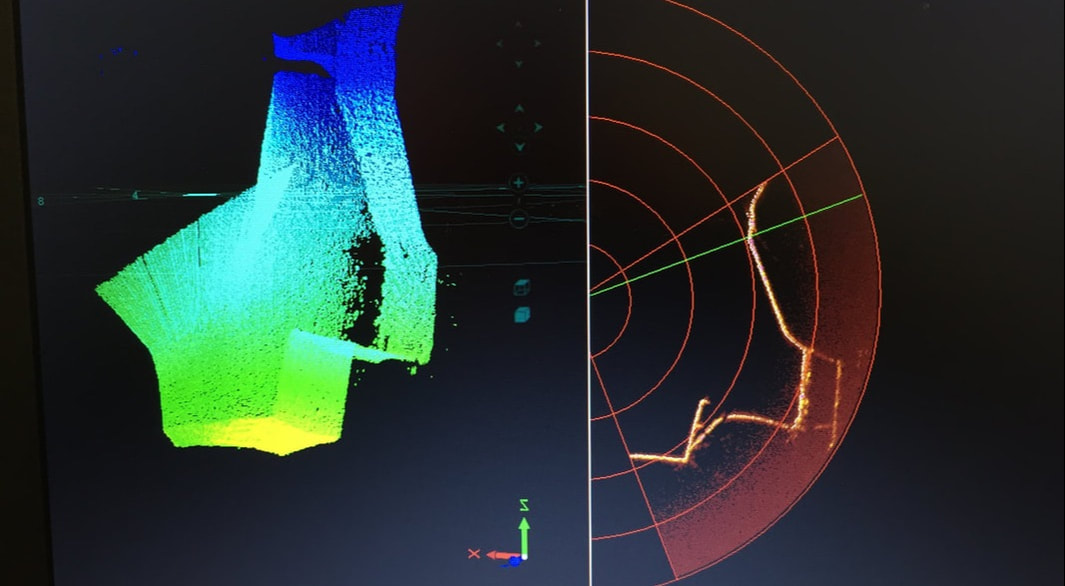

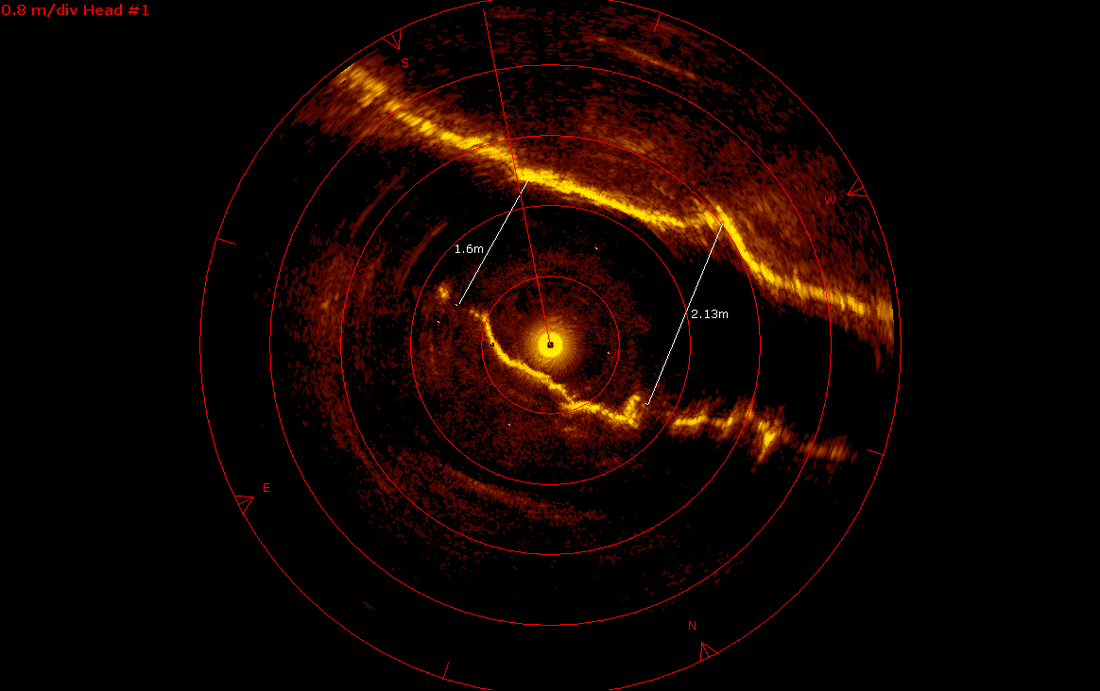

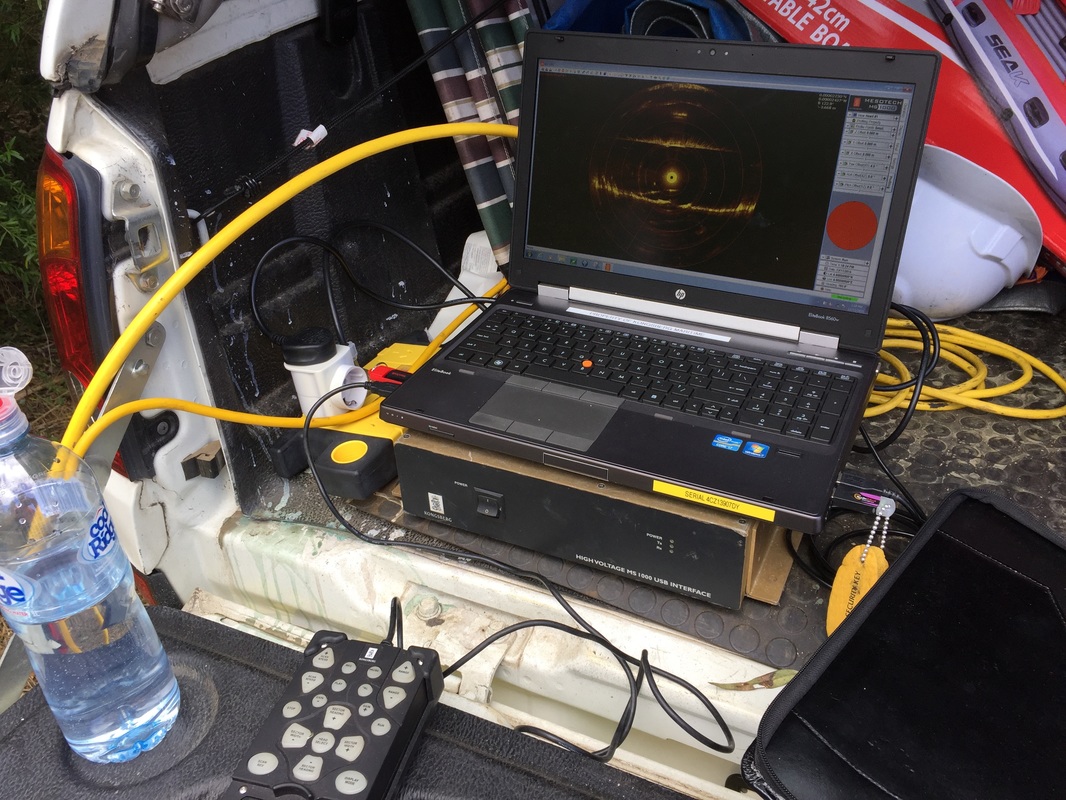

By combining our multiple resources (in this instance - Sonar, Commercial Vessel and Dive Team) we were able to provide the client with an optimal solution with minimal downtime. ROV Innovations sonar staff were called out early Thursday morning to assist with the search and recovery of an Audi Q5 that had mistakenly used a boat ramp on the northern end of The Gold Coast to launch itself into the water. A manual search was attempted on Wednesday evening, however due to the failing light and high currents it was decided to utilise the MS1000 hi resolution scanning sonar technology to assist with finding the vehicle. Within 5 minutes of setting up, we had located the "probable location" of the car, triangulated the precise position from the sonar screen, and directed one of our recovery divers to the area. On confirmation that we had found the vehicle, the Heavy Duty Tow Truck used its winch to pull the Q5 back to the shore. Thanks to Allcoast Towing and Knights Heavy Towing for bringing us down to assist in their recovery of the vehicle. We hope to be able to assist with any future search and recovery jobs.

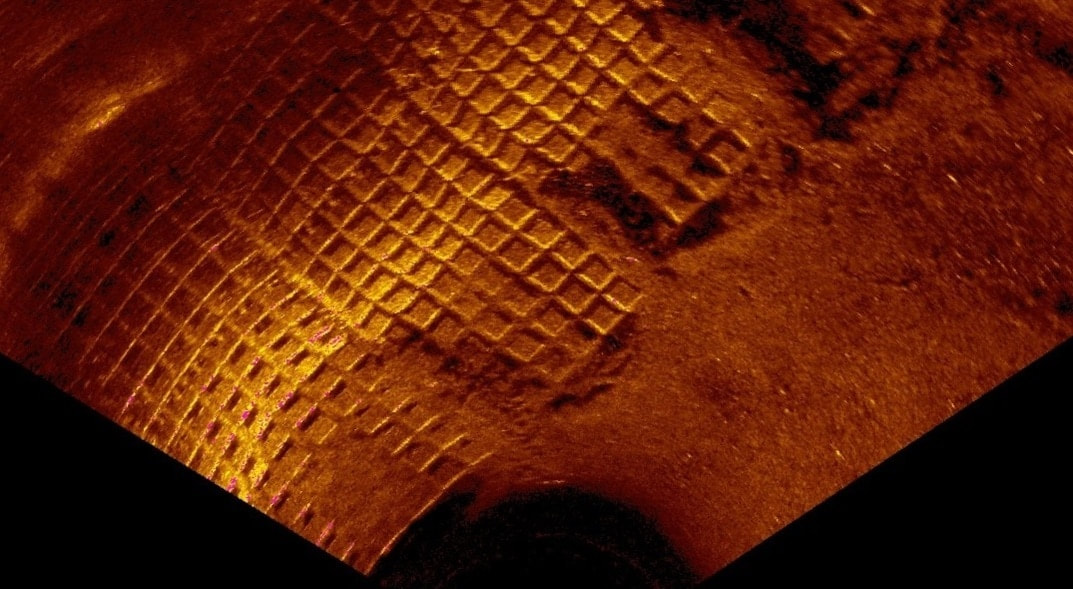

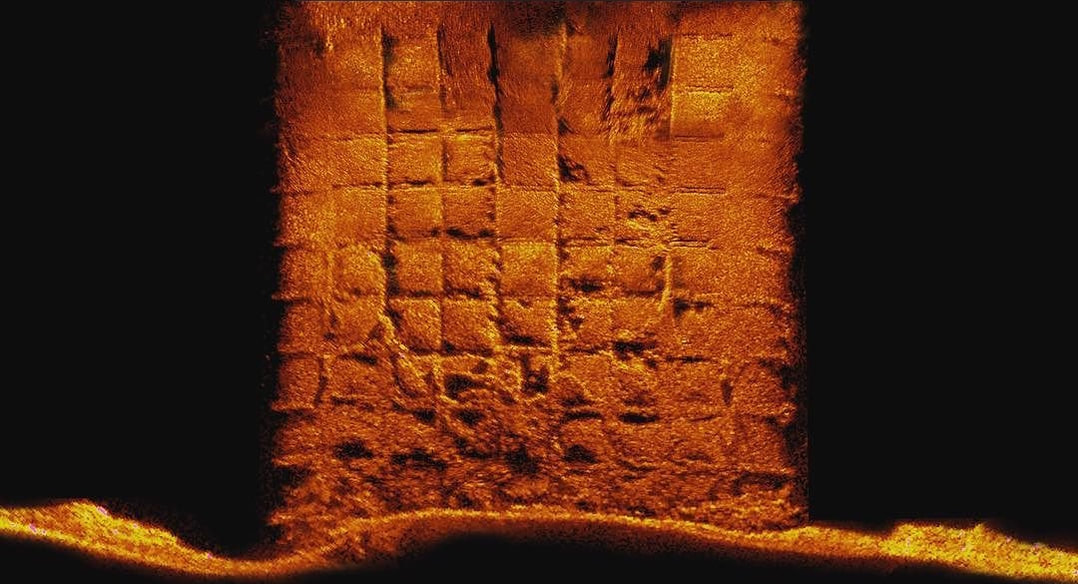

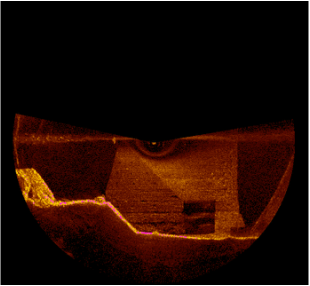

Hydro Tasmania contacted us for a project on one of their dams. Due to the recent flooding events that have hit all of the eastern and southern coast of Australia (a 1 in 200 year event), a significant volume of water was flowing into the northern lakes, discharging over several spillways Hydro Tasmania own and operate. Due to the high resolution scanning ability of the Kongsberg MS1000, we were able to show extremely clear images of the dam structure that hadn't been seen in almost 60 years since the dam construction. Due to the water being almost Zero Visibility, prior commercial dives in the dam plunge pool only hinted at various issues underwater, the sonar imagery we collected allowed the Engineers and Hydrographers to see everything that was occurring. Despite the environmental conditions, we completed the project without getting too wet and cold, and were able to provide a mosaic of the scans (as above) by the end of the day. The sonar scans gave Hydro Tasmania's engineers very useful information to assess the condition of the dam plunge pool..

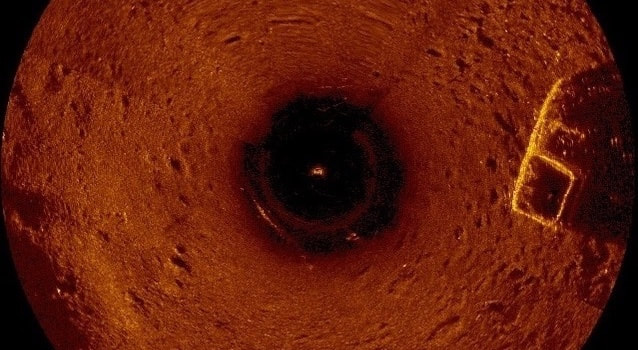

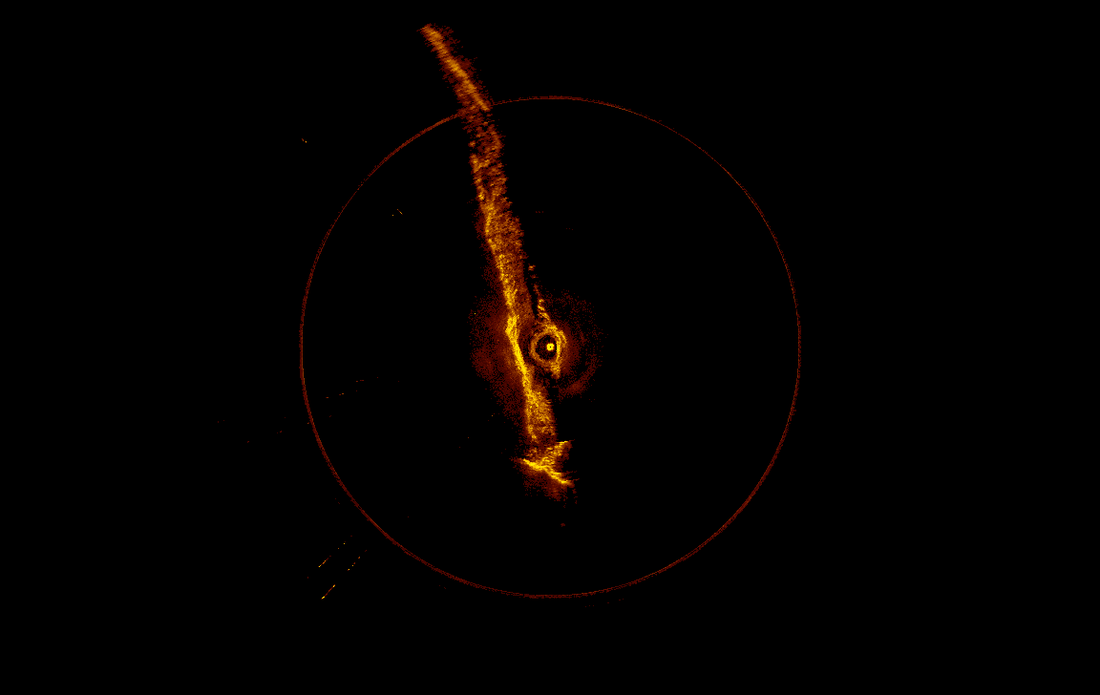

Wayne Griffioen from Tasman Geotechnics contacted ROV Innovations to assist with the possibility of surveying the extent of some flooded old coal mines in Northern Tasmania. The coal mine was discovered on some old maps of the area and was found whilst conducting standard boring to determine geological information of the area. The cave itself was only 800mm high, and located approximately 21m underground. They also had the equivalent water depth of 14m. After discussions with Wayne on the different options available, we settled on using a combination of a high resolution scanning sonar (Kongsberg MS1000), and a small, lightweight ROV for further exploration. The original borehole was only 90mm in diameter, therefore it had to be increased to allow the equipment through the hole and into the coal tunnels. Unfortunately, the positioning of the borehole on entry to the coal mine was off centre, therefore the sonar was situated within a small alcove in the cave, restricting the images of the western wall. However detailed measurements were gathered showing bends within the cave and also junctions where the mine branched in different directions. As the mine profiles were gathered every 100mm, we could determine the height, width and length of the coal mine section we were in and then compare this to the original drawings of the mine structure. A Videoray Pro 4 was also on site to obtain video footage of the mine itself as well as explore the various mine tunnels. Unfortunately due to the extremely high turbidity of the water within the mine, the camera on the ROV was only useful for obtaining video of the various rock layers, as well as their geological structure.

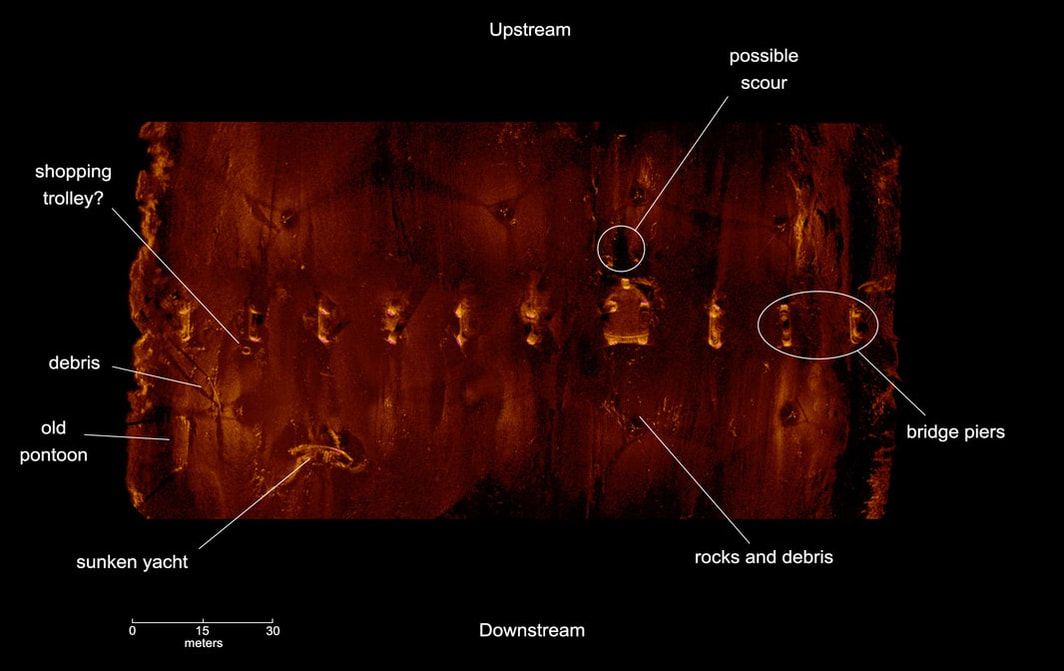

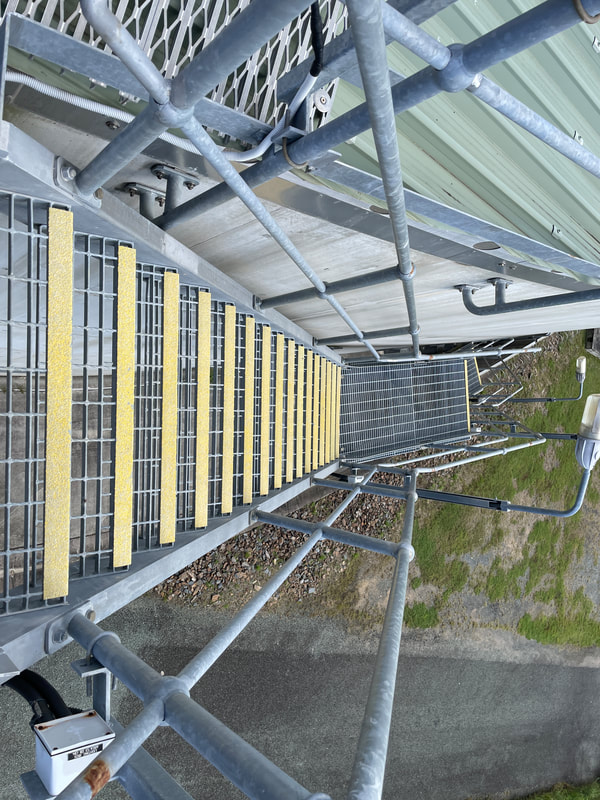

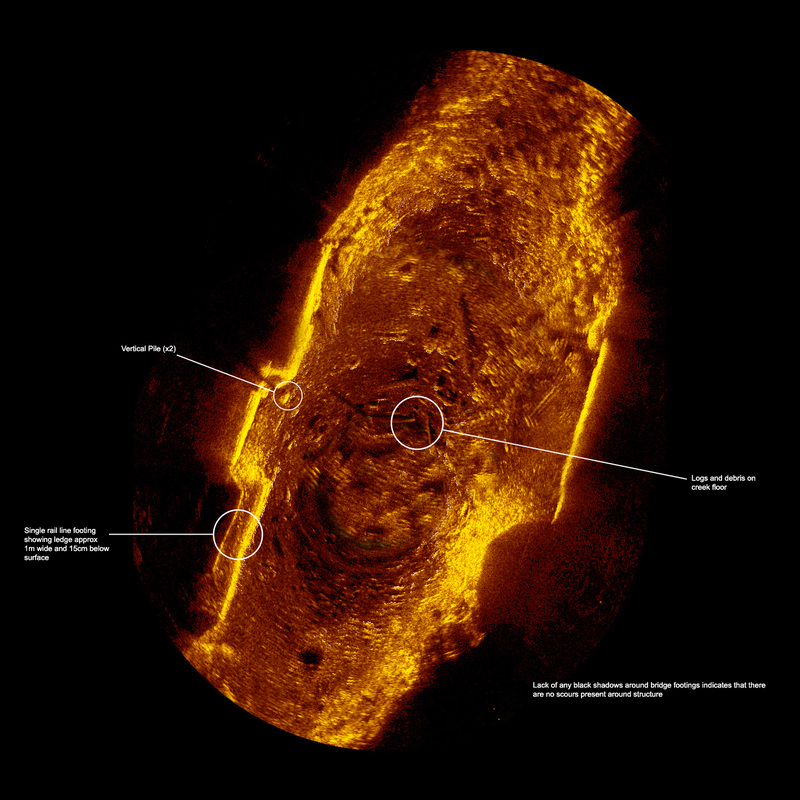

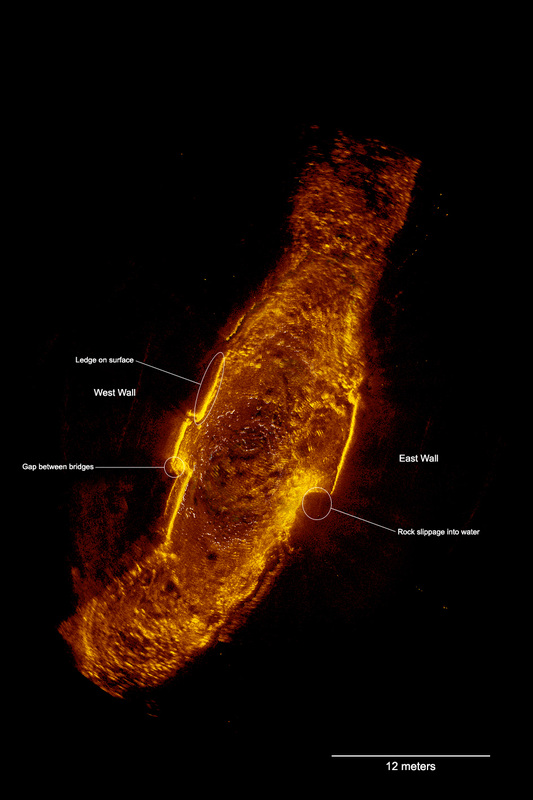

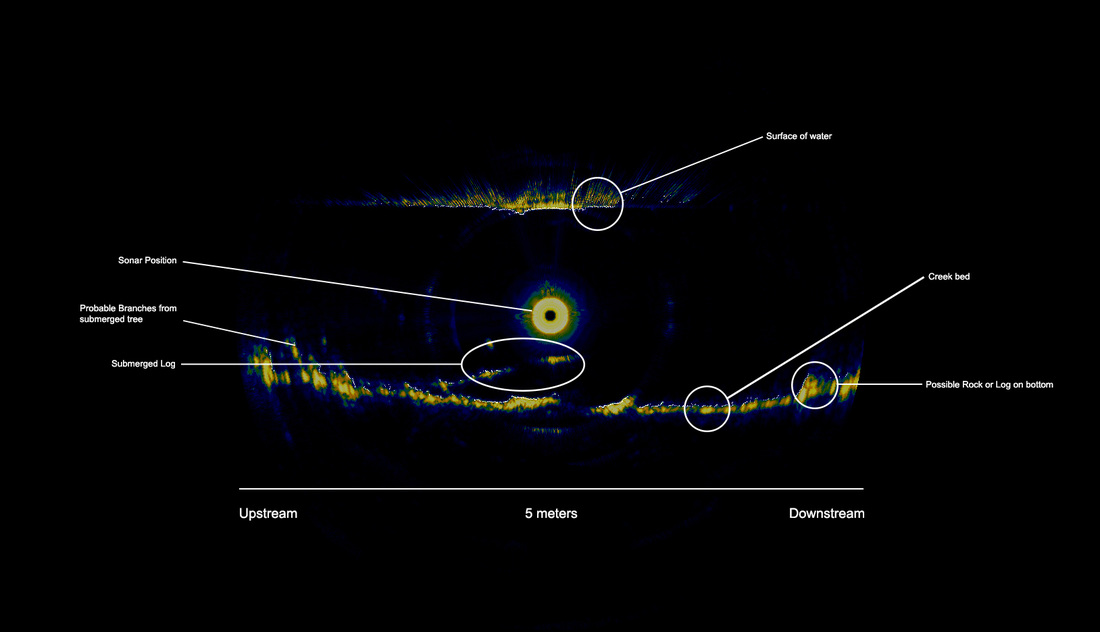

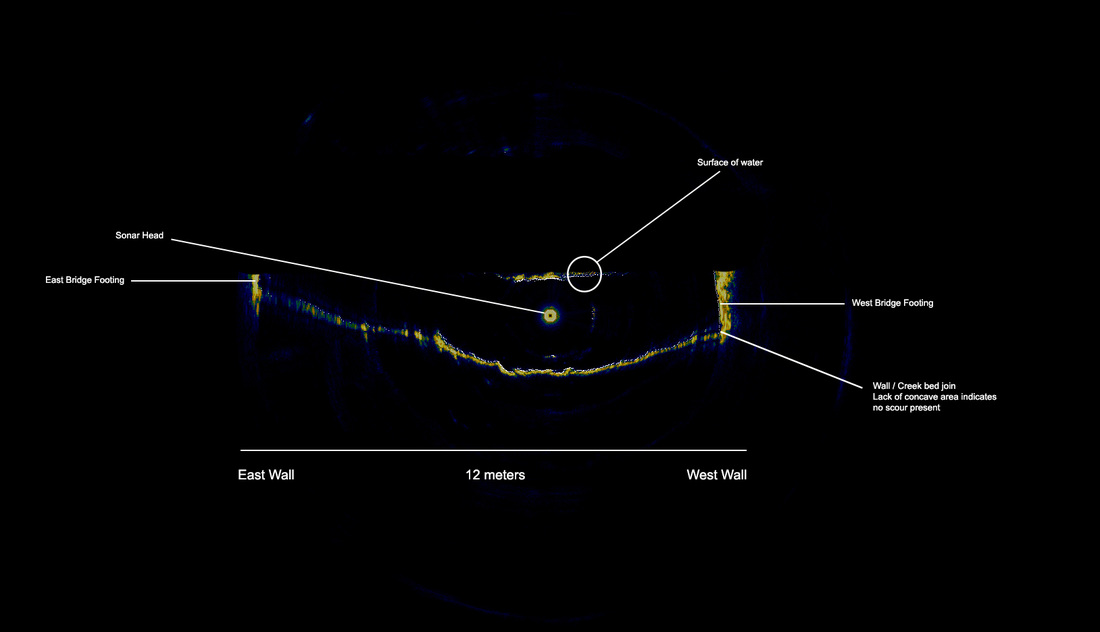

The data from the MS1000 sonar allowed us to determine the best location for additional boreholes to allow the deployment of the sonar for further mapping of the flooded coal mine. Thanks to Wayne Griffioen and Emily Bartlett from Tasman Geotechnics, as well as Simon Hills from Imbros for making this project run extremely smoothly despite the horizontal hail and extremely cold conditions on the day. We look forward to continuing the exploration of the coal mine once the additional boreholes have been drilled. ROV Innovations have recently conducted a thorough scanning sonar inspection of a creek crossing in Victoria for Sterling Group and Victoria Rail. The Kongsberg MS1000 high resolution scanning sonar was used due to the high turbidity of the creek which prevented any sort of visual inspection from being carried out, either by a commercial dive team or ROV. Multiple imaging scans were taken within the creek to show the bottom topography and indicate if there were any buildup of debris around the rail footings, and also to highlight any possible scouring. Due to the versatility of the Kongsberg MS1000 scanning sonar, creek profiles were also taken at multiple locations both longitudinally and transversely around the rail assets. This allowed a true profile of the area to be visualised, which in turn enabled the engineers to compile their structural report with an extremely high level of confidence High end equipment such as the Kongsberg MS1000 High Resolution Scanning Sonar enable traditionally difficult areas to be inspected and surveyed underwater. Areas with zero visibility and high currents (most Australian rivers) have traditionally been inspected with divers "feeling" the areas around the asset. This leaves extremely high levels of variation and increases the chance that areas are missed. The Sonar ensures that 100% of the asset and surrounding environment is assessed and mapped for the client, with minimum time taken and minimal OH&S risk as no staff are physically in the water. Thanks to David and Ben at Sterling for their assistance and hospitality, as well as Mark Atherton for his assistance with the MS1000

Contact us today to see how we can use our sonar and ROV solutions to assist with your next inspection. |

About UsROV Innovations provides High Definition underwater footage for industries such as Marine Conservation and Research, Australian Biosecurity, Customs, Documentary and Film Makers, Oil and Gas industries, and AQIS to name a few. Categories

All

Archives

April 2023

|

ROV Innovations.... Servicing Australia and the Pacific

Underwater ROV Inspections

Brisbane Gold Coast Newcastle Sydney Canberra Melbourne Hobart Adelaide Perth Darwin Auckland Fiji Vila Tonga Apia Rarotonga PNG

Underwater ROV Inspections

Brisbane Gold Coast Newcastle Sydney Canberra Melbourne Hobart Adelaide Perth Darwin Auckland Fiji Vila Tonga Apia Rarotonga PNG

Our Services |

Applications |

ROV Innovations |

ROV Innovations is a pioneering company providing positive, safe, and environmentally compliant outcomes for our clients.

We provide ultra Hi-definition (4K) underwater ROV inspections and surveys for industries such as Marine Conservation, Marine Research, Australian Biosecurity, Customs, Documentary and Film Makers, Oil and Gas industries, and AQIS through Remote Operated underwater Vehicles (ROV’s).

We provide ultra Hi-definition (4K) underwater ROV inspections and surveys for industries such as Marine Conservation, Marine Research, Australian Biosecurity, Customs, Documentary and Film Makers, Oil and Gas industries, and AQIS through Remote Operated underwater Vehicles (ROV’s).

© 2020 ROV Innovations | Queensland Australia | [email protected] | Mob +61 402 284 435

RSS Feed

RSS Feed