|

We have recently conducted underwater and aerial condition assessments for 5 SEQWater potable reservoirs in Alexandra Hills, Narangba, and Ferntree in South East Queensland for GHD. The 5 potable water tanks were inspected over the course of three days, with strict sterilisation procedures being followed for all equipment entering the reservoirs. As per our standard operating procedure whenever operating with potable water, all equipment was sterilised with 200ppm active chlorine and left to soak for a minimum of 30 minutes, including the ROV, all tether, ropes and tarps that were used to keep the ROV and equipment clean on the base as well as the roof of the reservoirs. Our High Definition Seamor ROV enabled the GHD Engineers to confidently assess the underwater internal structures of the reservoir, including ladders, wall and floor joins, scours, probes, mixers, columns, and also any buildup of debris or sediment. All of the inspections were completed on time and within budget, thanks to the organisation and planning from Rhett and Danny from GHD, as well as Russell from SEQWater. We look forward to conducting more inspections for them in the upcoming months.

0 Comments

David from Christopher Contracting contacted ROV Innovations to conduct an internal reservoir roof inspection for SEQ Water. With the ability for 2 high definition cameras to be deployed from our ROV, as well as 4 ultra bright LED floodlights, 100% of the internal roof was surveyed and inspected within the allocated time and on budget. Once the project was completed and all footage checked for QA purposes, we then took a peek at the underwater assets in the reservoir to show Charles and the guys and girls at the SEQ Water WTP the condition of the asset.

Thanks to the friendly and courteous staff from Christopher Contracting and SEQ Water - we look forward to working with you both again in the near future. ROV Innovations recently conducted multiple internal fire tank inspections for FCF - Fire and Electrical clients PUMA Energy. PUMA had recently taken over multiple fuel stations on the Fraser Coast and required their fire deluge systems inspected to ensure that they complied with current legislation. Despite the 3 1/2 hour mobilisation each way to the 2 PUMA Energy sites, the inspections were all completed same day, and on budget. The high definition video footage and 12 megapixel images were compiled and sent off to FCF next day ensuring that they could quickly and efficiently compile the reports to PUMA with minimum turnaround time.

Attached are just some of the images provided to FCF for their reporting to PUMA Energy. ROV Innovations were recently hired to fly down to Melbourne to inspect a cooling system tank for Hewlett Packard. The system had previously been inspected by a different company however due to the turbidity within the tank, the footage obtained was unusable. A second difficulty was the physical restrictions getting the ROV into the tank. Pipelines along the roof restricted the space on entry to the tank, however the modular ability of the Seamor ROV allowed the float to be removed and the ROV to squeeze past the pipe works and into the cooling tank. With the High Definition 1080p30 Sony camera, and VisionClear live video optimisation, we were able to see just enough to confirm the bottom condition of the tank. Considering the extremely high level of particulate material within the cooling system, we were impressed with the performance of the ROV and vision clear technology. Unfortunately we could not provide a complete inspection with the confidence required due to the water parameters, but offered some solutions for the HP team to proceed. With all LED spotlights on the ROV (over 6000 lumens), we lost total ROV visibility (including lights) at only 70cm depth. While in the building, the sprinkler fire tank was also inspected, allowing the HP maintenance staff to view live its internal condition. The walls, floor, pipe penetrations, and electronics were viewed in true hi-def allowing technicians to make the relevant calls on future maintenance of the fire protection system. Thanks to Eddie and Stephen at HP for their assistance on the day, and making a rather difficult inspection as easy as possible.

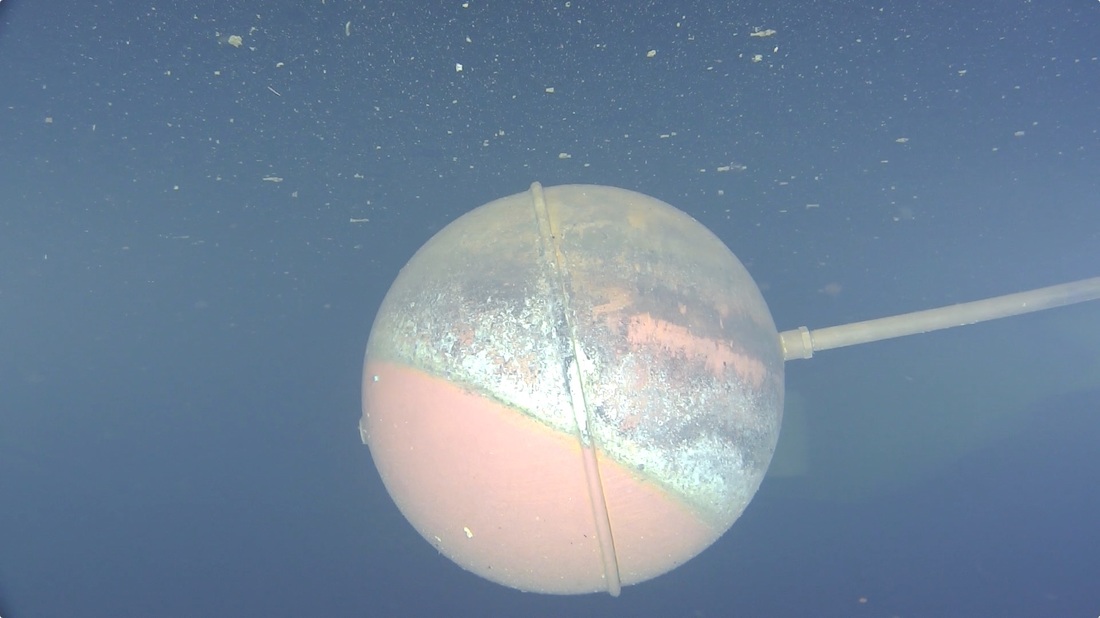

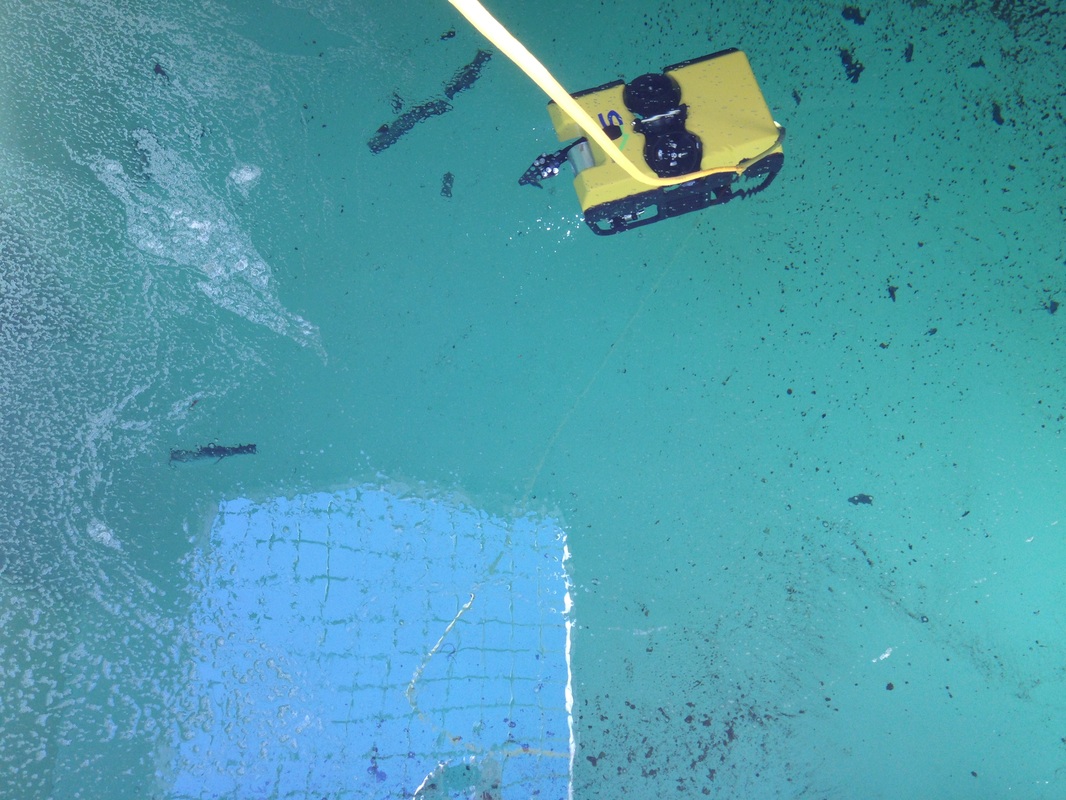

David Toohey, Senior Water Quality Scientist at Gippsland Water, contacted ROV Innovations regarding the use of Seamor advanced ROVs for inspecting the range of potable storage tanks and reservoirs. Due to the positive feedback from other owners of Seamor ROVs within Australia, the water quality team at Gippsland purchased a 300T "ATOM" ROV, specifically designed for water tank inspections. David decided to add a few additional features to increase the functionality of their ROV such as a single function manipulator, 2 additional LED floodlights, rear camera, VisionClear video enhancement, and top mounted HD camera for reservoir roof inspections. We delivered Gippsland's new ROV and conducted onsite training for David, Jamie, and Wayne over the course of three days, initially starting in one of the managements new swimming pools (thanks Chris!), then proceeding to the Clearwater Treatment plant, then finally onto one of the more difficult concrete in-ground reservoirs. The guys picked up all features of the ROV extremely quickly, realising features like the Auto Depth and Auto Heading functionality greatly assisted in their ability to fly the ROV without disturbing the minimal sediment within the tanks. The VisionClear video enhancement proved to be a great benefit, specifically with the Digital Wide Dynamic Range feature and the Colour enhancement. The additional lighting was perfect for older concrete tanks where all light seems to be absorbed by the walls and floor. And in the tanks with supporting columns and cross beams, the rear camera worked well so the guys could see exactly where they had been and ensured their tether was not wrapped in and around any potential snags. One of the main benefits of using robust commercial grade inspection class ROVs, such as Seamor, in the Potable Water industry where water quality is paramount, is that the ROV can be quickly and efficiently sterilised before and after each inspection, ensuring that nothing is introduced to the towns water supply. The added manipulator on the ROV lets Jamie, the water quality technical officer, collect water quality samples from anywhere within each reservoir, enabling Gippsland water to maintain a very high level of confidence in the product they deliver.

Fireboar's James Gavin contacted ROV Innovations to conduct internal inspections of 2 Fire suppression tanks at International Paints, South Brisbane. Due to the high risk environment, operations needed to be carried out while the fire system was still operational. Due to the size and ability of the Seamor thrusters, the additional external lights, and the zoom capabilities of the Sony High Definition camera, ROV Innovations was able to conduct both inspections quickly, efficiently and safely while the deluge tanks were still operational. This not only saved time and money for the client, it gave them additional piece of mind that their deluge tanks were inspected with the only high definition ROV capable of performing these inspections in Australia. Feedback from both the high def video footage and written report was very positive - "I have to say, the report and the video you have sent out is first rate. The way you set them out is excellent. All the guys here are very impressed, thanks Michael." - James Gavin, Fireboar. ROV Innovations were also commended on their very thorough and precise JSEA and SWMS from the International Paints Health and Safety Officer. An abridged version of one of the deluge tank inspections is shown below. |

About UsROV Innovations provides High Definition underwater footage for industries such as Marine Conservation and Research, Australian Biosecurity, Customs, Documentary and Film Makers, Oil and Gas industries, and AQIS to name a few. Categories

All

Archives

April 2023

|

ROV Innovations.... Servicing Australia and the Pacific

Underwater ROV Inspections

Brisbane Gold Coast Newcastle Sydney Canberra Melbourne Hobart Adelaide Perth Darwin Auckland Fiji Vila Tonga Apia Rarotonga PNG

Underwater ROV Inspections

Brisbane Gold Coast Newcastle Sydney Canberra Melbourne Hobart Adelaide Perth Darwin Auckland Fiji Vila Tonga Apia Rarotonga PNG

Our Services |

Applications |

ROV Innovations |

ROV Innovations is a pioneering company providing positive, safe, and environmentally compliant outcomes for our clients.

We provide ultra Hi-definition (4K) underwater ROV inspections and surveys for industries such as Marine Conservation, Marine Research, Australian Biosecurity, Customs, Documentary and Film Makers, Oil and Gas industries, and AQIS through Remote Operated underwater Vehicles (ROV’s).

We provide ultra Hi-definition (4K) underwater ROV inspections and surveys for industries such as Marine Conservation, Marine Research, Australian Biosecurity, Customs, Documentary and Film Makers, Oil and Gas industries, and AQIS through Remote Operated underwater Vehicles (ROV’s).

© 2020 ROV Innovations | Queensland Australia | [email protected] | Mob +61 402 284 435

RSS Feed

RSS Feed